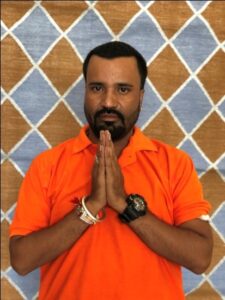

Quality Controller

Designing–

At Vimla International, we have a team of skilled designers, Kratika Khandelwal and Komal Sharma, who work closely with our customers to create customized CADs for their rug designs. Our designers work tirelessly to ensure that every detail of the design is precisely according to the buyer’s requirement. They use state-of-the-art technology and software to create the perfect CAD that is then sent to the weaver for production.

The CAD is a vital part of the rug-making process as it provides the weaver with an accurate blueprint of the design. This helps ensure that the rug is made exactly to the buyer’s specifications, with the correct size, shape, and colors. Our designers are skilled at creating CADs for all types of rug designs, from intricate traditional patterns to modern abstract designs.

Kratika Khandelwal and Komal Sharma understand the importance of customer satisfaction and strive to deliver high-quality CADs that meet their expectations. They work collaboratively with the buyer to ensure that the design is precisely what they are looking for. Once the CAD is approved, our weavers can begin the rug-making process, confident that they have all the necessary information to create a beautiful, high-quality rug.

At Vimla International, we take pride in our commitment to delivering customized rugs that meet our customer’s unique requirements. Our team of designers is an integral part of this commitment, ensuring that every rug is made to the highest standards of quality and craftsmanship. Whether you are looking for a traditional rug design or a modern abstract pattern, our designers are here to help you create the perfect rug for your space.

Kratika Khandelwal

Komal Sharma

Dyeing–

At Vimla International, we take great pride in the quality of our rugs, and one of the essential factors that contribute to their beauty is the color. Our Senior Color Dyer, Jogendra Singh and Nanag Ram Yogi, with their 12 years of experience, are responsible for color matching from the buyer’s color code.

Jogendra Singh and Nanag Ram Yogi are experts in color dyeing and work closely with our designers to ensure that the colors used in our rugs are consistent with the buyer’s color code. They use the latest color-matching technology and techniques to ensure that the colors in the rug are vibrant, rich, and long-lasting.

The color dyeing process is a critical step in rug-making, and our senior color dyers take great care to ensure that every rug is made to the highest standards of quality. They work with precision and attention to detail to ensure that the colors are evenly distributed throughout the rug, resulting in a beautiful and uniform appearance.

Jogendra Singh and Nanag Ram Yogi understand the importance of color in creating a beautiful rug. They take pride in their work and are committed to delivering rugs that meet the highest standards of quality and craftsmanship. Their expertise ensures that every rug we produce is a work of art, with colors that are rich, vibrant, and long-lasting.

At Vimla International, we are committed to providing our customers with the highest quality rugs. Our Senior Color Dyer, Jogendra Singh, and Nanag Ram Yogi are an integral part of this commitment, ensuring that every rug we produce meets the highest standards of quality and craftsmanship. If you are looking for a rug that is beautiful, durable, and made with the highest quality materials, look no further than Vimla International.

Jogendra Singh

Color Matching -

At Vimla International, we take great care in ensuring that the colors used in our rugs are consistent and of the highest quality. After the yarn has been dyed, Padam Parewa and Narayan Saini work together to match the colors from the original color roll.

Padam Parewa and Narayan Saini are experts in color matching and have many years of experience in the rug-making industry. They use their expertise to carefully match the colors in the yarn to the original color roll, ensuring that every rug is made to the highest standards of quality.

The color-matching process is a crucial step in rug-making, as it ensures that the colors used in the rug are consistent and vibrant. Padam Parewa and Narayan Saini understand the importance of color in creating a beautiful rug and take great pride in their work.

Once the colors have been matched, the yarn is ready to be woven into a rug. The weavers use the dyed yarn to create beautiful patterns and designs, using traditional weaving techniques that have been passed down through generations.

At Vimla International, we are committed to producing rugs of the highest quality, and the work of Padam Parewa and Narayan Saini is an essential part of this commitment. Their expertise in color matching ensures that every rug we produce is a work of art, with colors that are consistent, vibrant, and long-lasting.

If you are looking for a beautiful and high-quality rug, look no further than Vimla International. Our rugs are made with the finest materials and crafted by expert weavers and dyers who take pride in their work. With a wide range of patterns and designs to choose from, we have the perfect rug to complement any decor.

Narayan Saini

Padam Parewa

Plying -

At Vimla International, we take great pride in supporting women artisans and empowering them to be part of the rug-making process. Kesar Devi was the first woman artisan to join our team, and she paved the way for many other women to follow in her footsteps.

Today, we have a team of skilled women artisans, including Sunita and Puni Devi, who are responsible for plying the yarn after the color approval process. Plying is the process of twisting two or more strands of yarn together to create a stronger, thicker yarn.

After the yarn has been dyed and the colors have been matched, Sunita and Puni Devi carefully open the yarn in single threads. They then twist the threads together, using a spinning wheel, to create a single, strong strand of yarn.

This process requires great skill and attention to detail, as each strand of yarn must be carefully twisted to ensure that the final product is strong, durable, and of the highest quality. Sunita and Puni Devi take great pride in their work and are committed to creating the best possible yarn for our weavers.

By employing women artisans like Kesar Devi, Sunita, and Puni Devi, we are not only creating beautiful, high-quality rugs but also providing opportunities for women to become financially independent and contribute to their families and communities.

At Vimla International, we are committed to supporting and empowering women artisans and creating a more sustainable and equitable future for all.

Kesar Devi( First women artisan) and Sunita

Loom Inspection-

At Vimla International, we are committed to ensuring that every rug we produce meets the highest quality standards. To achieve this, we have a team of skilled professionals, including Ronak Sisodiya and Akshay Rawat, who are responsible for checking orders on the loom.

Ronak and Akshay visit the loom to ensure that the order size, color, weaving quality, and lead time are all in line with the buyer’s requirements. They carefully inspect each rug and take photos to send to the buyer, ensuring that any issues are addressed quickly and efficiently.

Their attention to detail is critical, as even the smallest flaw can impact the final product’s quality. By catching any issues early on, we can ensure that our customers receive the highest quality rugs possible.

Ronak and Akshay take pride in their work and are committed to upholding our company’s high standards of quality and customer satisfaction. They work closely with our weavers and other team members to ensure that every order meets our exacting standards.

At Vimla International, we believe that our commitment to quality sets us apart from our competitors. By investing in skilled professionals like Ronak and Akshay, we can continue to produce beautiful, high-quality rugs that our customers can enjoy for years to come.

Ronak Sisodiya

Akshay Rawat

Checking -

At Vimla International, we take quality control seriously, and that is why we have a team of experts who are responsible for checking every rug that comes off the loom. Narayan Saini, Mallu Khan, and Manish Sharma are members of this team, and they work tirelessly to ensure that every rug meets our high standards.

When the rug arrives from the loom, Narayan, Mallu, and Manish carefully inspect it from both sides, looking for any flaws or inconsistencies. They use the order sheet as a reference to ensure that the size, color, and quality match the buyer’s requirements.

They check for any imperfections such as knots, fraying edges, or uneven weaving. If they find any issues, they work with our team of weavers to correct the problem, ensuring that every rug that leaves our factory is of the highest quality.

Narayan, Mallu, and Manish understand that our customers expect the best, and they are committed to ensuring that every rug meets our exacting standards. They take pride in their work and are dedicated to upholding our reputation for quality and excellence.

At Vimla International, we believe that our commitment to quality sets us apart from our competitors. By investing in skilled professionals like Narayan, Mallu, and Manish, we can continue to produce beautiful, high-quality rugs that our customers can enjoy for years to come.

Manish Sharma

Mallu Khan

Washing -

At Vimla International, we understand that washing and cleaning a rug is an important step in the production process. That’s why we have a team of skilled professionals led by Hukum Parewa, Moti Meena, and Mohan Meena, who are responsible for washing and cleaning each rug to ensure that it is clean, fresh, and ready for sale.

The washing process begins with the rug being carefully laid out and inspected for any remaining debris or dust. The team then uses a combination of brushes and stones to clean the rug, removing any dirt or stains that may have accumulated during the weaving process.

To ensure that the rug is properly protected, Hukum, Moti, and Mohan use a combination of water and chemicals that are safe and effective at protecting the rug from insects and other pests. They are highly skilled in the use of these chemicals and take great care to ensure that they are used in the correct proportions and applied safely.

After the rug has been thoroughly washed, it is laid out to dry in the sun. This process ensures that the rug is completely dry and ready for the next stage of production. Hukum, Moti, and Mohan oversee this process, making sure that the rug is laid out flat and protected from the sun’s harmful rays.

The washing and cleaning process is an important step in the production of our high-quality rugs. At Vimla International, we take great pride in our attention to detail and our commitment to providing our customers with the best possible products. By investing in skilled professionals like Hukum, Moti, and Mohan, we can ensure that every rug we produce is clean, fresh, and ready for sale.

Mohan Meena

Hukum Parewa

Finshing -

After washing and drying a rug, the final step in the production process is to finish the edges to the buyer’s specifications. This is a crucial step that ensures the rug looks polished and professional.

Soni Sharma, Gopal Kharol, and their team are experts at this task. They carefully cut the threads to create a neat, even edge that won’t fray or unravel. They also take into account the buyer’s requirements, such as the shape of the rug or the color of the thread used for finishing.

Attention to detail is key in this step, as any mistakes can be costly and time-consuming to fix. Soni, Gopal, and their team take great care to ensure that each rug is finished to perfection, so that it can be enjoyed for years to come.

Their work is a testament to the importance of skilled craftsmanship in the production of high-quality textiles. From washing and drying to finishing the edges, every step in the process requires precision and expertise. And Soni, Gopal, and their team are masters of their craft, dedicated to creating beautiful rugs that will be treasured by their owners for generations.

Gopal Kharol

Packing -

Once the rug has been finished with precision, it is then sent to the packing unit where it is carefully prepared for transport. This is an essential step in ensuring that the rug arrives at its destination in perfect condition.

Vijendra Singh, Sitaram Jogi, and Kanhaiya Lal are the skilled workers responsible for packing the rug. They take great care in their work, knowing that the rug is a valuable and delicate item that needs to be handled with utmost care.

They offer two types of packing for the rug – roll packing and fold packing. In roll packing, the rug is carefully rolled up and secured with tape to prevent any movement during transportation. In fold packing, the rug is folded neatly and securely wrapped in plastic to protect it from any damage.

The team is very alert and attentive during the packing process, ensuring that the rug is packed tightly and securely. They make sure that all corners and edges are protected and that there is no chance of the rug getting damaged in transit.

Their dedication to their work and their attention to detail ensure that every rug is packed with the utmost care and professionalism. Vijendra, Sitaram, and Kanhaiya are an integral part of the rug-making process, and their work is crucial in ensuring that the rug arrives at its destination in pristine condition.

In conclusion, the packing unit is the final stage in the rug-making process. The skill and dedication of the workers, such as Vijendra, Sitaram, and Kanhaiya, ensure that the rug is packed with care and precision, ready to be transported to its new home. Their work is a testament to the importance of skilled craftsmanship in the textile industry, and the result is a beautiful rug that will be enjoyed for years to come.

Sitaram Jogi